The universal solution

Our all-rounder for CO2 and fibre lasers

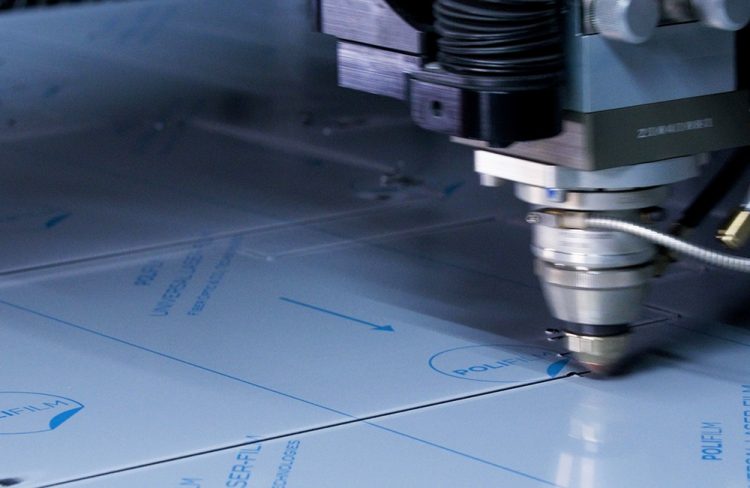

One film for every challenge

The PF584CS is extremely versatile and an ideal all-rounder

The PF584CS laser protection film is the classic in our range. No wonder: it is extremely versatile, suitable for both CO2 and fibre lasers, guarantees the best processing results and reduces rejection rates.

The film has a high adhesive strength which enables it to adapt optimally to the substrate and guarantees optimum performance even with unfavourable cutting conditions.

One film, endless applications

Guaranteed process optimisation and cut quality with maximum flexibility

- Excellent adhesion

to rough and structured surfaces - No bubbling

especially on problematic surfaces - Highest quality cutting

without burring or risk of carbon deposits

- Homogeneous film quality

virtually gel-free - Tear resistant

with excellent forming characteristics - Easy to removal

no residues or tearing

- Up to six months UV resistance

for outdoor applications - Customised print

at customer’s request - Suitable for CO2 lasers

One film for both technologies

Would you like to learn more? We will be happy to help you!

Excellent adhesion

Adhesive formulation adapts to different substrates

A clean cut result

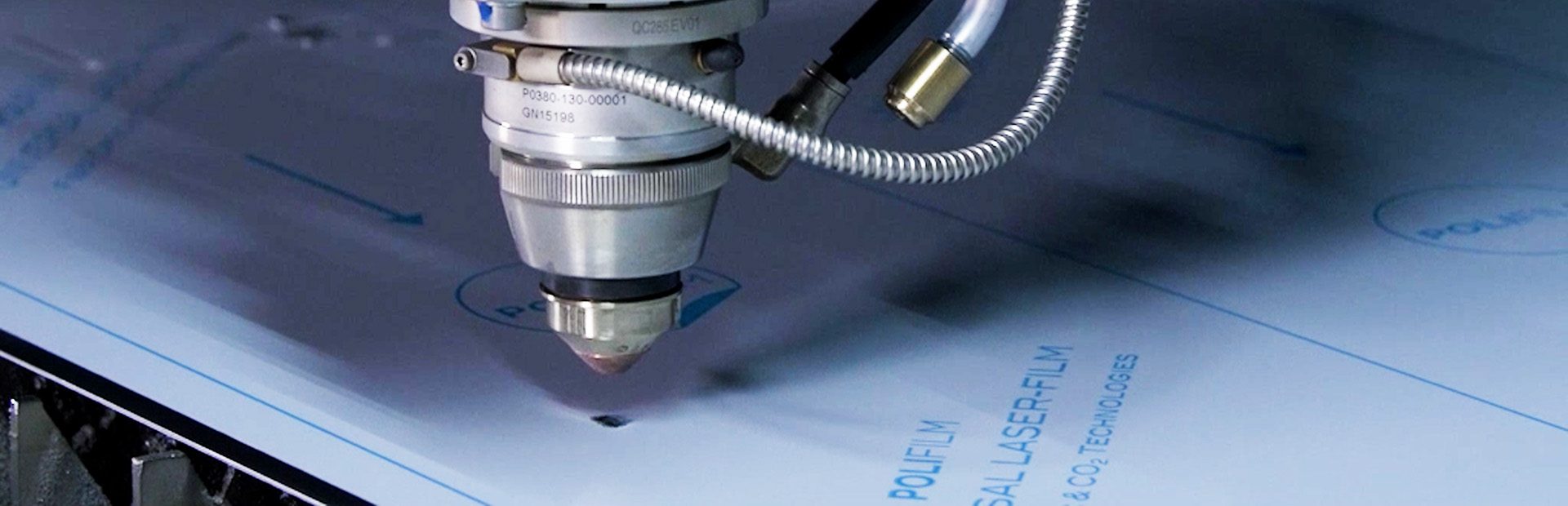

The initial piercing with the laser is the moment of truth. If there is a lack of adhesion, the pressurised cutting gas cannot escape properly and instead collects between the protective film and the metal surface. Bubbles form and impair the focus of the laser beam as well as the targeted gas flow. The cut edges can be of inferior quality and, in the worst case there is a risk of rejection.

Optimised soft adhesive formula

The natural rubber adhesive of the PF584CS combines improved flow behaviour with excellent wettability. It penetrates even better into different surface structures and ensures a secure anchorage. The film therefore adapts particularly well to the substrate and guarantees perfect adhesion. The risk of bubble formation is significantly reduced.

Highly effective under difficult conditions:

- For rough and very structured surfaces

- At very low processing temperatures

- Overstretched lamination or excessive tension

- In extended cutting processes e.g. low power laser,very thick sheets or poorly absorbing material

Would you like to learn more? We will be happy to help you!

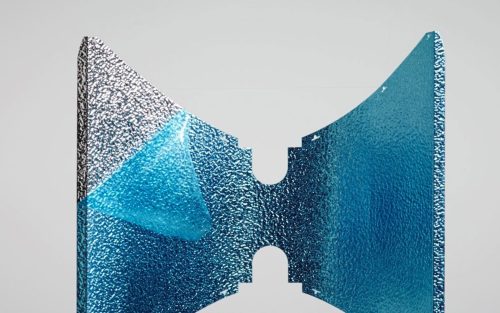

Tear resistant and workable

Outstanding formability

Its optimal forming behaviour makes our PF584CS the ideal protection for manual, semi-automated and fully automated forming processes. For sheets that are bent, folded or punched. What’s more, the carrier film is particularly homogeneous and has a low gel level. As a result there are no uneven areas that could damage the metal surface under the forces applied.

Universal laser protection film needed for thin sheets?

The processing of thin sheets requires specially tailored protection. Here you will find the right universal laser protection film.

You might also be interested in

Further film solutions for laser cutting and metal processing

Do you have any questions? We are happy to support you!