The clean cut

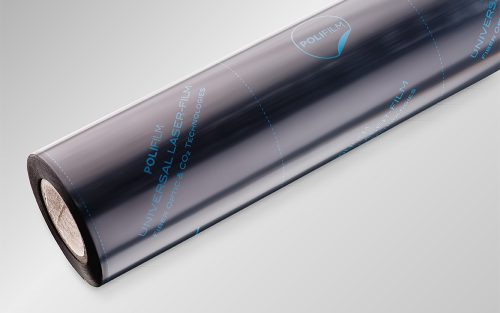

Protective films for CO2 and fibre lasers

- Optimum adhesion

Bubble formation is prevented - High quality cutting

Precise cuts – burr and carbon free - Easily removed

Quick and safe removal – without leaving residues

Increased efficiency and quality during laser cutting

POLIFILM PROTECTION supplies unrivalled protective film solutions

Laser cutting of sheet metal places extreme demands on the protective film. If you want to ensure maximum productivity and optimum quality, you need a high performance solution that is suitable for both the laser technology and processing procedures.

We have the solution, with a wide range of high performance laser protection films in our portfolio. Laser protection films for fibre or CO2 lasers, for conventional, reflective or particularly thin sheets. Whether for cutting, bending, forming or stamping.

Our laser protection films – for your benefit

The right solution for every production requirement

Premium protection at full speed

Laser protection film: PF84C

100% absorption of the fibre laser. Optimum cutting results at any speed, especially with highly reflective metals.

Constant visual control

Laser protection film: PF34C

Highly transparent laser protection film. Constant quality control and assurance of the correct surface selection. Ideal for coloured and structured sheets.

The trio for thin metal sheets

Laser protection films: PF582C | PF82C | PF32C

Perfectly tailored adhesive strength: Thin sheets are optimally protected, against bending during lamination and removal.

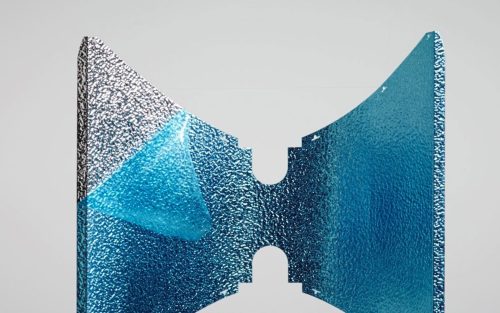

Universally adaptable solution

Laser protection film: PF584CS

The solution for CO2 and fibre lasers. Flow optimised adhesive formulation. Bubble-free certainty during cutting. Assured adhesion when folding and bending.

Would you like to learn more? We will be happy to help you!

You might also be interested in

Our film solutions for the protection of metals

Do you have any questions? We are happy to support you!