Protective films – tailor-made

for your requirements

Excellence in application technology. Dominance in development.

Tailor-made protection

Our promise to you: When we’ve found a solution and you’re satisfied, so are we! Our task is always to provide you with the best solution available. To this end, our application engineers analyse your specific parameters and requirements down to the smallest detail and select the optimum solution for you. Should the solution not exist, our colleagues from our research and development departments are always happy to work with you, to develop a protective film individually tailored to your application.

What you can rely on

- Precise analysis of your requirements

- Innovative technologies and technical advice

- R&D specialists and state-of-the-art laboratories

- Individual customer and bespoke solutions

- A worldwide network of development experts

- The combined knowledge of a global leading group

Excellence in adhesive development

Our knowledge, our formulations, our production

from water and solvent based acrylic adhesives,

natural rubber adhesives through to synthetic rubber adhesives.

As the market leader in protective films, we are your most trusted development partner in the industry who can cover the entire range of adhesive systems in use today. The collective knowledge of our global application engineers located throughout our own centres of excellence for acrylic and rubber based adhesive systems, is second to none. This enables us to determine the optimum adhesion and release properties for each application and to develop the precise adhesive formulations for our customers application, every time. Even in the most technically challenging situations, our steadfast methodological approach allows us to examine every customer requirement and always find the optimal solution.

Excellence in films

Knowledge sharing within the POLIFILM Group

The optimum coated protective film needs the optimum carrier film. Choosing the correct formulation, the right properties and production technique of any carrier film, is a huge challenge in itself. At POLIFILM, we can offer the same expertise and specialist knowledge here in one group: In close co-operation with our colleagues at POLIFILM EXTRUSION, our application specialists put together exactly the right backing film properties that are optimally suited to your application. So that the film easily meets your requirements in terms of longevity, weather and UV resistance as well as mechanical and thermal resilience.

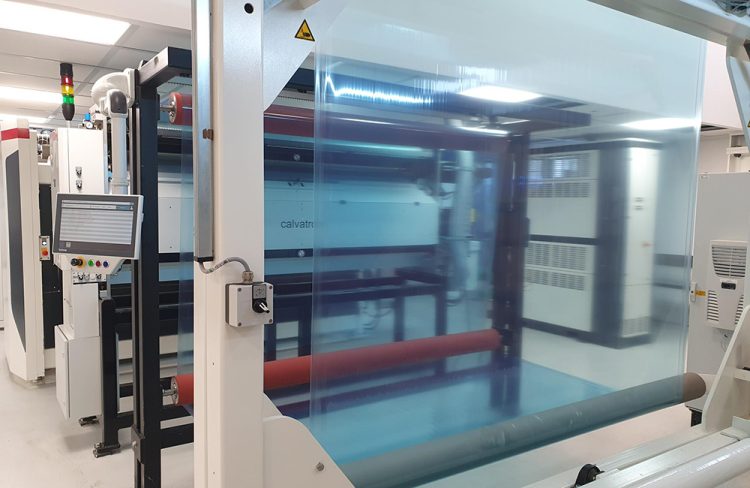

Excellence in Co-extrusion

Co-extruded protective film solutions: Non-coated

With POLEG, our production and development site in Israel, and

our second production plant, POLI-COAT, located in Germany, we guarantee our customers maximum flexibility.

More than twenty years of experience, comprehensive technological know-how in the extrusion of cast and multi-layer films, as well as state-of-the-art, automated production technology: all this is behind every single co-extruded protective film solution from POLIFILM PROTECTION. In our in-house technical centre, our Co-ex specialists develop adhesive and film construction with very specific properties and combine them into a high-performance surface protection film, tailor-made to the respective customer requirement. Our special feature: The adhesive component of our raw materials used for the co-extrusion of our protective films are developed in-house and compounded using our own on-site equipment.

This might also be of interest

Learn more about POLIFILM PROTECTION