Films for rigid packaging

Flexible solutions for your rigid packaging needs

- Customised development

of PE & PP solutions - Tailored to the needs of the food and pharmaceutical industry

- For various applications & packaging types

Would you like to learn more? We are happy to advise you!

Wide range of options for trays, blister packs & more

Our lamination films & films for interlayers

Regardless of whether it is meat packaging, berry trays, non-food packaging or blister packaging, laminating films and intermediate layers have an impact on the function of the entire packaging. This is particularly true when it comes to optimising the closure and the processability of the laminate solution. Specially tailored to rigid laminates and laminates for rigid packaging, we offer you the right PE or PP solution for every application, regardless of the contents, from powdery to greasy.

What we offer you

- Perfectly matched PE & PP films

for rigid laminates & rigid composites - For all common lamination processes

Thermal and adhesive coating lamination - High process stability

to optimize your packaging

- For reliable closure

through ideal sealing properties - Satisfying opening experience

peel & non-peel options - Decades of experience

and customised development

Films for thermal lamination

Optimum sealing and thermoforming properties

We offer you customised laminating films for your rigid laminate. Adapted to the thermoforming applications commonly used for trays, our laminating films for thermal lamination impress with their properties such as optimum seal ability and thermoforming. Choose from a wide range of property profiles such as peel and non-peel functions.

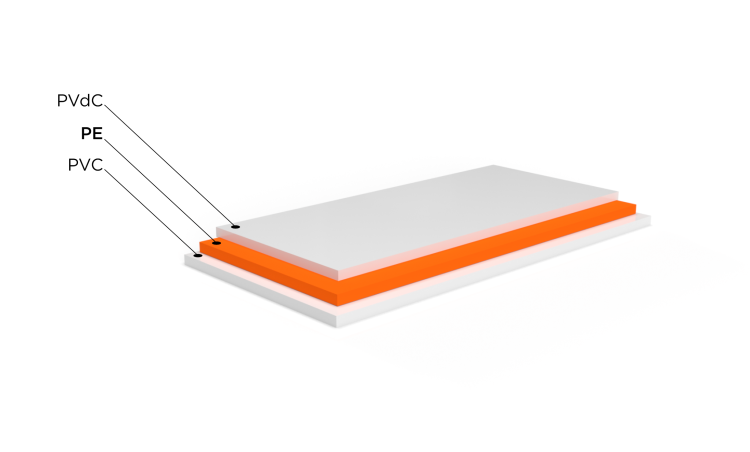

PE interlayer for blister packaging

We offer PE films as an interlayer for the laminate of your blister packaging. The formulation of our PE film, which is specially tailored to your application, ensures effortless lamination and a stable bond. By utilising the typical properties of polyethylene, the film also guarantees a breakage-free winding of the laminated composite and optimises thermoforming.

You might also be interested in

Excerpt from our portfolio – with and without barrier