Premium protection

for fibre laser cutting

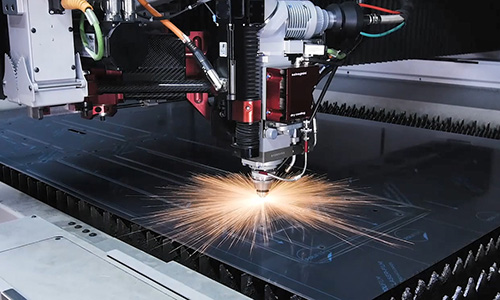

Excellent results at full power

Maximum speed without compromise

Increased productivity, Increased output, increased efficiency

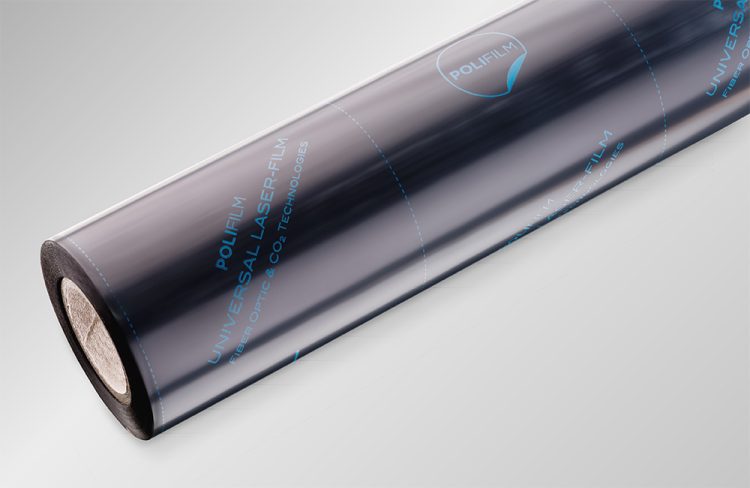

If you still restrict the cutting speed when using a fibre laser, we have good news. With our special film formulation and special additives, we have optimally adapted the absorption capacity of the PF84C laser protection film to the wavelength of the fibre laser. As a result, it converts all of the energy of the laser into heat when cutting.

In production, this means even at maximum speed, the laser cuts through both the product and protective film in a single step whilst still maintaining its first class cut quality making your processing more efficient. The same applies when processing aluminium and other highly reflective metals. Here too, the absorption improves significantly thereby increasing the cutting process efficiency.

High-tech film for high-tech applications

Maximum speed whatever the cutting complexities

- Maximum speed

when cutting with the fibre laser - Highest quality cutting

without burrs or carbon traces

- Less cleaning required

Reduced laser nozzle contamination - Easily removed

No residue, no tearing

- Six months UV resistance

Ideal for outdoor applications - Equally suitable for CO2 lasers

One film for both technologies

Would you like to learn more? We will be happy to help you!

The PF84C does even more…

Assured quality reduces rejections and reworking

Optimum adhesion, bubble-free cutting

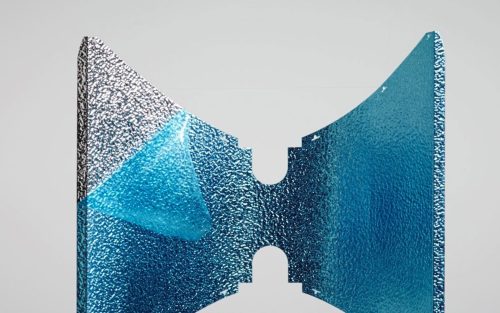

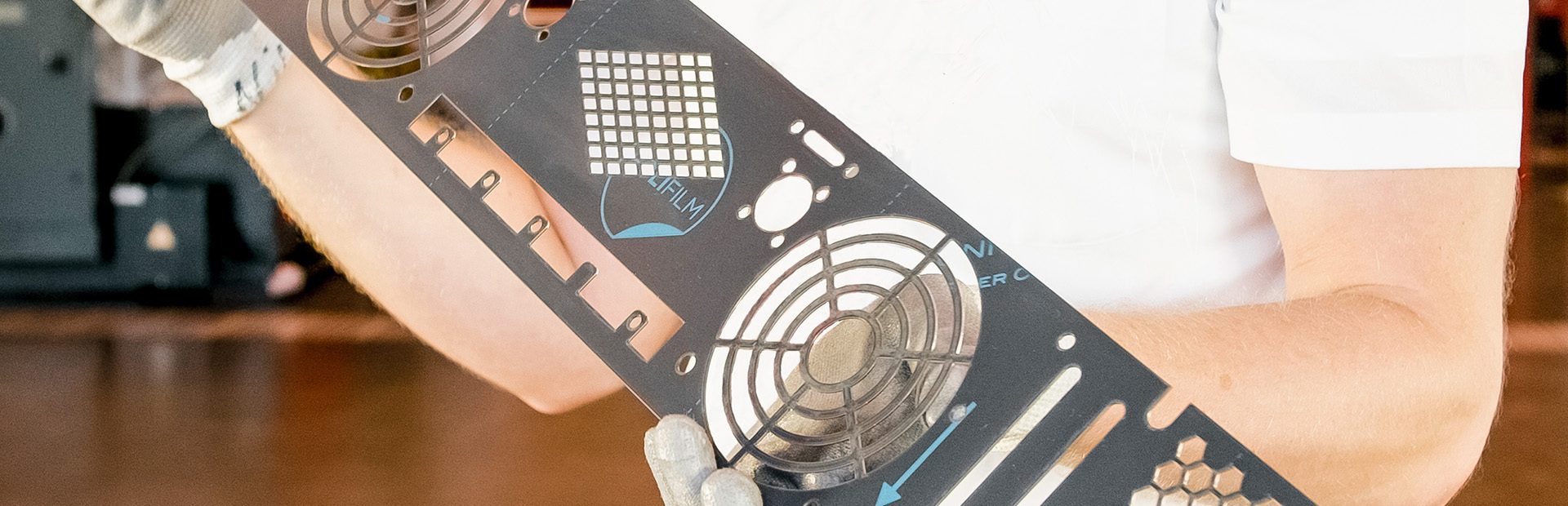

The adhesive in the PF84C adapts perfectly to the substrate, ensuring ideal adhesion and prevents bubble formation during piercing or cutting. Even complex cutting geometries with clean, burr free edges at maximum cutting speed are possible without compromise. Because our laser protection film is extremely tear resistant, it can withstand bending, folding or punching whilst still being easily removed without leaving any residue.

Reduced laser nozzle contamination

But that’s not all. Because with the PF84C the laser nozzle gets less dirty than with a conventional protective film, you can extend your maintenance cycles, optimise your machine running time and significantly increase your productivity.

Would you like to learn more? We will be happy to help you!

Discover more

in our video!

Download now!

In a nutshell – all advantages of the

PF84CS at a glance.

Highest speed cutting of thin sheets?

Do you often process thin sheets with a thickness of less than 0.8 mm? Then we have a protective film specially optimised for this application for you.

You might also be interested in

Further film solutions for laser cutting and metal processing

Do you have any questions? We are happy to support you!