Designed for thin sheets

Optimum protection for delicate metal

Safe removal without bending

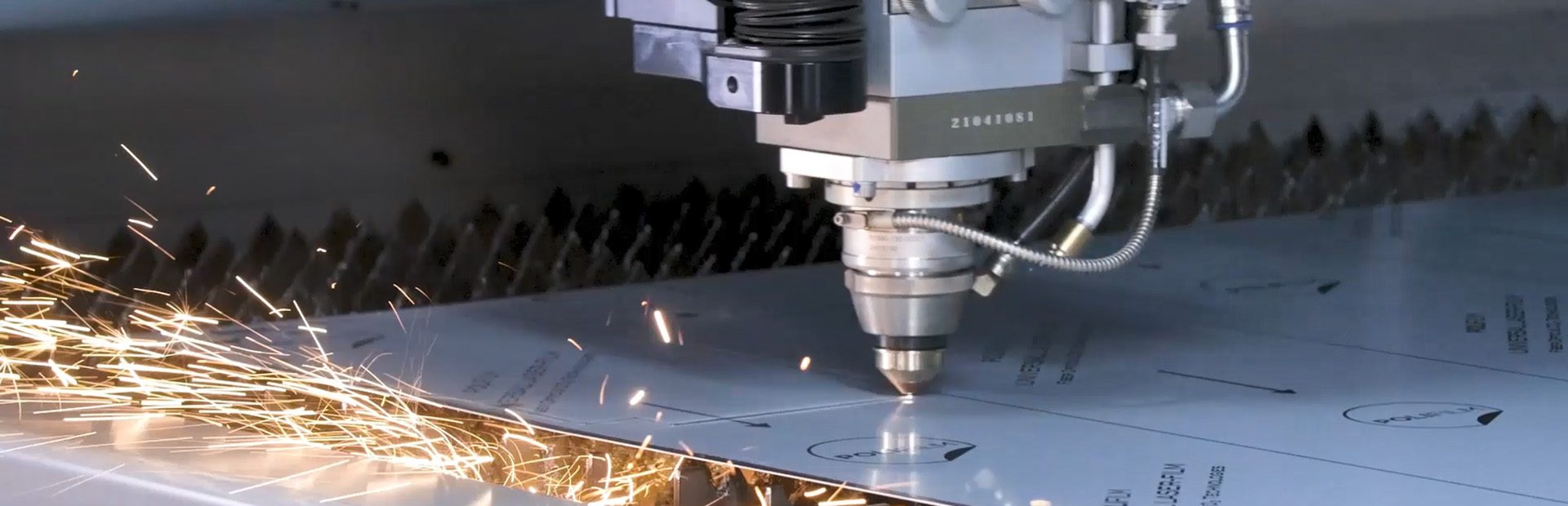

Thin sheets susceptible to bending require specific protective films

Thin sheet metal is extremely popular in the manufacture of household appliances. But the thinner the sheet, the higher the risk of undesired bending or buckling especially when removing the protective film. That’s why we have optimised several protective films specifically for sheets up to 0.8 mm thick.

As a processor of thin sheets, you can benefit from numerous advantages of our protective films, they speed up your processing, reduce your rejection rate and increase your productivity. You can also provide your customers with immaculately clean, burr and carbon free cut edges.

Three application areas, three film technologies

Each film ensures efficiency, increased productivity and quality in its area of application

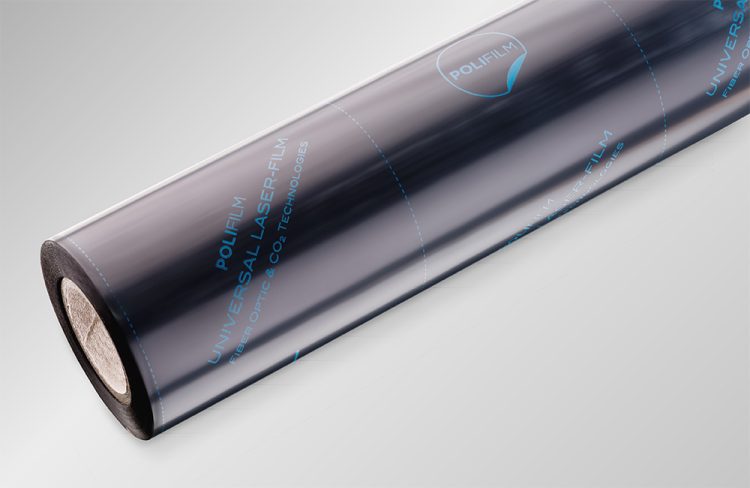

The universal laser protective film for reliable all-round protection

The transparent fibre laser protection film for constant visual control

The fibre laser protection film for maximum cutting speeds

- Three film technologies

for different applications - Optimised unwinding

tension-free lamination

- Removal without bending

easy, quick and residue-free - Excellent adhesion

optimised for the application

- Perfect cut edges

clean, burr and carbon free - Increased productivity

thanks to optimal processes

Would you like to learn more? We will be happy to help you!

Process and application optimised

Thin sheets place special demands on the protective film

Tension free lamination

Our laser protection films for thin sheets have a tailor-made unwinding quality designed for thin sheet processing. As a result, they can be unwound quickly and laminated without tension. The sheet remains absolutely flat, so that it can be optimally processed and cut with the same high quality.

Without bending the sheet. Without tearing the film.

Easy, safe removal

The special laser protection films for thin sheets also show their strengths when it comes to removal. Their special adhesive formulation and tear resistant structure allow them to be removed from the sheet without leaving any residue, easily, quickly and, most importantly, without the risk of bending, regardless of the size and geometry of the shape or cutting design.

Uncompromised protection

Like the laser protection films for conventional sheets, the films for thin sheets make no compromises when it comes to protection and optimal results. They guarantee excellent adhesion and effectively prevent blistering during piercing and cutting.

Would you like to learn more? We will be happy to help you!

Discover more

in our video!

Download now!

In a nutshell – all the benefits of our adhesion optimised films at a glance.

Are you cutting thicker metal sheets?

Here are our solutions

Do you have any questions? We are happy to support you!