Innovative Laser Protection Film conserves resources whilst reducing costs

- POLIFILM PROTECTION has developed their PF582CS, a laser protection film that is only 60 µm thick.

- Due to its considerable material savings and lower adhesive requirements, it saves raw materials and has a reduced CO2 footprint.

- Suppliers and users can improve their environmental impact whilst at the same time benefiting from increased productivity and optimum surface protection

Modern stainless steel surfaces allow the use of new, considerably thinner protective films resulting in advantages for both the environment and industry.

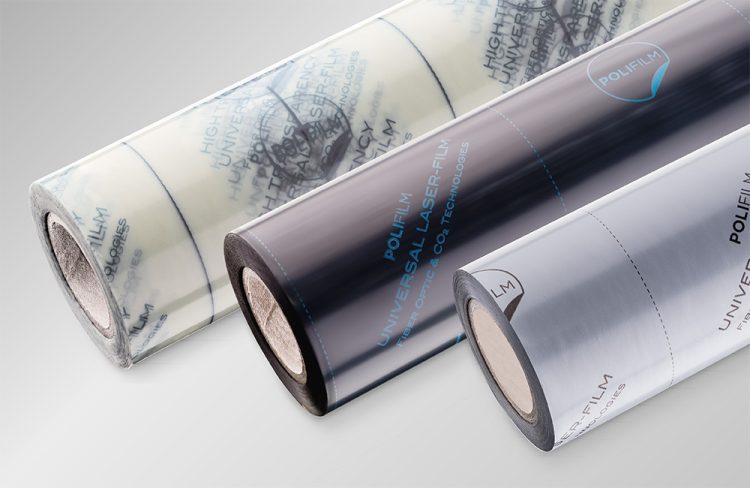

The global protective film specialist POLIFILM PROTECTION has introduced a material saving laser protection film for stainless steel sheets with 2B or 2R surfaces. The PF582CS is only 60 µm thick and requires a reduced amount of adhesive, saving resources and making it a cost-efficient solution.

Stainless steel with particularly smooth surfaces, especially those with a 2B or 2R finish, have been very popular for some time and modern fibre lasers are now also optimally suited for cutting film protected stainless steel sheets. The result is that the use of protective films with lower adhesive strengths and reduced thickness is now possible.

POLIFILM PROTECTION has taken advantage of these new developments in terms of film thickness and adhesive strength and developed a resource saving and cost-efficient laser protection film. At 60 µm, it is significantly thinner than standard laser protection films and requires less adhesive than its conventional counterparts. This has a positive effect on its CO2 footprint, with upto 41 percent less CO2 is produced during production compared to that of a standard POLIFILM PROTECTION laser protection film with a thickness of 100 µm. A service centre that chooses the thinner film can therefore save about as much greenhouse gas as a car emits on average over 379,000 kilometres.

Uncompromising, process efficient protection

Due to its low adhesive strength, the film has a low unwinding force. Despite its reduced thickness, it can be unrolled without overstretching and laminated without tension. It also performs just as well in terms of removal thanks to the application optimised adhesive, it is easy to remove and counteracts bending, especially with thin sheets. As you would expect from POLIFILM PROTECTION, the PF582CS reliably protects against damage during processing.

Thomas Mähner, Head of Development at POLIFILM PROTECTION’s production and development site in Germany: “With the PF582CS, we have optimised changes in the market into concrete customer benefits and offer service providers and users an opportunity to improve their cost and environmental balance, with process efficiency and quality at the highest level.”