New generation of protective films for fibre laser processing significantly increases productivity

- POLIFILM PROTECTION introduces a new generation of protective films for fibre laser processing at Blechexpo 2023.

- They boast a 100 percent absorption rate, allowing the fibre laser to achieve clean, burr-free cutting edges even at maximum speed.

- A special adhesive formulation prevents the formation of bubbles, rendering pre-piercing unnecessary.

Highest quality at maximum speed – Cutting process time increased by up to 20 Percent

At Blechexpo 2023, POLIFILM PROTECTION unveils a new generation of protective films for fibre laser processing. Thanks to their ideal film and adhesion properties, these process optimized solutions contribute significantly to increased productivity and quality efficiencies. At the same time they help enhance the customer’s environmental and climate footprint.

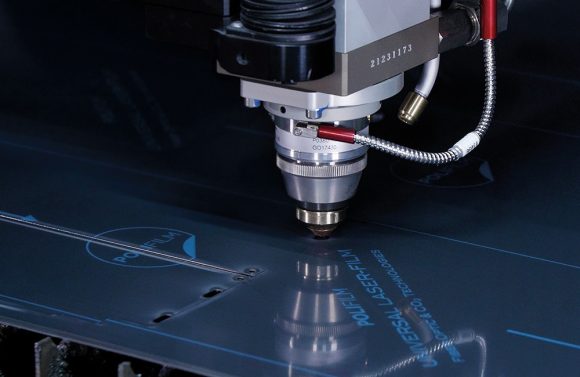

Two properties make the new protective film generation a winner for users: Firstly, POLIFILM PROTECTION has tailored the new protective films to the wavelength of the fibre laser using special additives, giving them a 100 percent absorption capability. As a result, the laser beam is neither scattered nor reflected, allowing its energy to be completely converted into melt heat. Even when the fibre laser operates at maximum speed, it consistently produces clean, burr-free cutting edges and therefore ideal item for further downstream processes. The cutting process is increased by up to 20 percent, noticeably improving productivity.

Secondly, the new protective film generation thanks to its soft and optimally adhering adhesive formulation, prevents bubble formation especially at the critical moment of the initial piercing. The need for preventive pre-piercing, which users typically employ to prevent bubble formation associated process interruptions and higher rejection rates, can be eliminated. This increases processing by an average of up to 35 percent, depending on the applied methods and machinery.

Cost Savings of Over € 100,000 Per Year

“Our new protective films optimize the operating times of the fibre laser, reducing energy consumption and labour costs per item,” explains Thomas Mähner, Head of Development at POLIFILM PROTECTION. “In a two shift operation with average utilization, they can save the user over €100,000 per year.” Moreover, the films reduce costs in other areas as well; scrap rates decrease, rework is minimized and the laser nozzle requires much less frequent cleaning. Finally, the protective film easily accommodates subsequent processing steps such as edge forming, bending, or punching and can be removed afterwards with minimal effort and no residue.

Responsible Resource Management

Ultimately, POLIFILM PROTECTION’s new protective film generation helps companies achieve their sustainability goals. Reduced scrap rates mean no waste of natural resources and because energy can be used much more efficiently, the individual item’s CO2 footprint ultimately improves. Sustainability has played a crucial role at POLIFILM for many years. The group has extensive expertise in recycling and the use of recyclates and recently established POLICYCLE, a subgroup dedicated to the entire product lifecycle. This encompasses the collection of used films, recycling and the continuous development of recyclates. POLIFILM therefore has all the necessary control systems in place to incorporate recyclates into even demanding film solutions.

POLIFILM PROTECTION at Blechexpo: Hall 01, Stand 1703