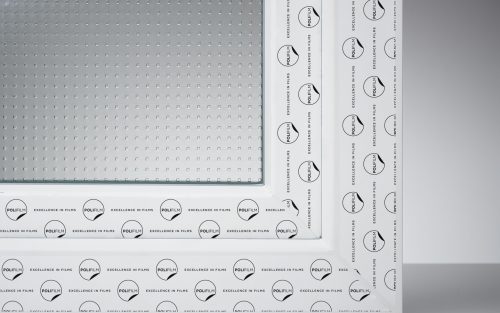

Protection films

for thermoforming

Tear-resistant, powerful adhesion and easy to remove – for ideal thermoforming of plastics

Would you like to know more? We will be happy to help you!

The shape changes. The protection remains the same.

Our protective films can withstand even strong thermoforming.

Our co-extruded protective films for thermoforming plastics have all the prerequisites to withstand the mechanical and thermal stresses that occur during hot forming. However, they not only withstand the forming process, but also adhere optimally during the moulding process thanks to optimally dosed restoring forces and adhesive properties. And they reliably protect the surface.

In addition to uncompromising surface protection, our protective films for thermoforming also ensure greater efficiency and process reliability: our coloured transparent films, for example, allow quick visual inspection. And our co-extruded thermoforming films allow easy removal without residues. Rework is no longer necessary, thus improving your process efficiency.

Thermoforming films by POLIFILM PROTECTION

Advantage for your production

- High temperature resistant

- Very tear resistant – can cope with any forming

- Stable and reliable adhesion

- Easy and residue-free removal

- Homogeneous film quality – low gel level

- Process-optimised film thicknesses

- No sticking to the thermoforming tools

- Films 100% recyclable

Our thermoforming solutions at a glance

The right protective film for your specific needs

Line bending & shallow thermoforming

Our temperature-resistant, co-extruded protective films for light thermoforming provide you with the optimum protective properties for your moulding process. They do not tear and ensure an ideal balance between necessary adhesion and optimal release properties.

Deep Thermoforming

Our co-extruded premium solutions meet every process requirement, even for deep and complex thermoforming. They are extremely temperature resistant and can easily withstand temperatures of up to 200° C without tearing or leaving film residues on the thermoforming tool.

Would you like to know more? We will be happy to help you!

For any plastic forming

we supply the perfect surface protection solution

This might also interest you

Protective films for pre-drying

As a specialist for protection during thermoforming, we naturally also have solutions for pre-drying plastics in our range. Our special protective films can remain on the surface during pre-drying without any problems and can be easily and cleanly removed again despite thermoactivation.

Would you like to know more? We will be happy to help you!

More about our product solutions

Protective films for plastic surfaces

Do you have any questions? We are happy to support you!