Films for edge bands

All round protection

Consistent quality

From bonding to the finished piece of furniture

In furniture design, edge bands play a significant role as they literally round off the appearance. Applied to the narrow side of the furniture panel, they not only seal the cut edges but also create a seamless visual transition, without any disruptive breaks. A wide range of print variations, gloss levels, and surface textures are available.

To ensure that the edge bands and their appearance are optimally protected from bonding through to completion of the piece of furniture, we offer you precisely tailored surface protection solutions. Our self-adhesive protective films preserve your edge bands securely and reliably from dirt, surface abrasion, and scratches – for a flawless end result.

Our range of services

Customized. For your application.

- Surface protection for various types of edge bands

such as melamine edge bands, HPL edge bands and thermoplastic plastic edge bands (made of ABS, PP, PVC, PMMA, PET) - Solutions for every surface finish

individually adapted to embossing structure, gloss level, and finish coat

- Suitable for all commonly used bonding methods

such as classic hot melt adhesive application, laser joining processes and hot-air as well as NIR (Near-Infrared) technologies - Easy, residue free removal

for effortlessly flawless aesthetics

Customized protection during processing

Your processes. Our films.

Ideally suited to your processing

We rely on unique formulations to balance the mechanical and thermal properties of the protective film to your processing requirements. This includes parameters such as excellent stretchability, high tear and abrasion resistance, as well as resistance to moisture and chemicals.

Precise adhesion

The secret to reliable and gentle film adhesion? Precisely tuned adhesive systems, formulations, and bonding strength. Our experts select all of these individually tailored to the material of your edge band and its specific requirements.

Would you like to learn more? We will be happy to advise you!

Clear quality

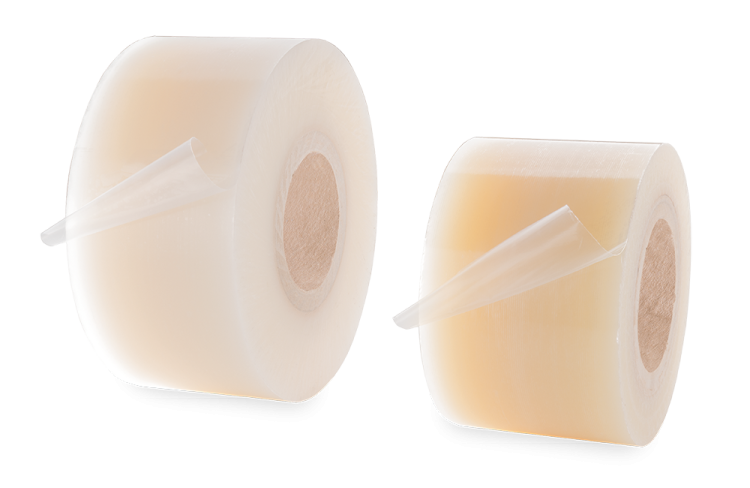

Our transparent solutions

Transparent protective films simplify many process steps by providing clarity. Whether in production preparation or manufacturing, they allow for a quick check to ensure the correct décor has been selected. They also prevent costly mix-ups and enable uncomplicated visual inspection during the ongoing processing, thereby reducing waste.

You might also be interested in

Additional protective film solutions for furniture manufacturing and interior design

Do you have any questions? We are happy to support you!